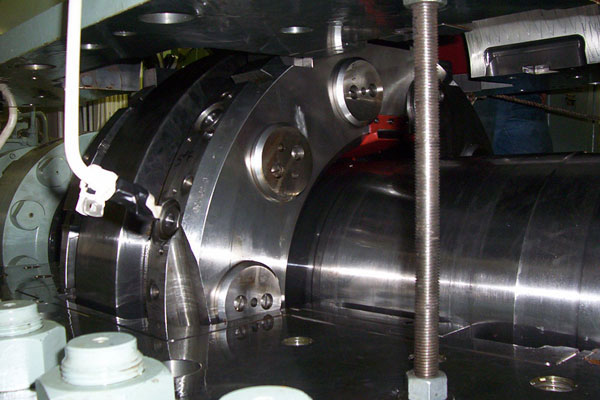

At IKAD Engineering, our dedicated machine shops offer our clients a comprehensive range of general and specialist machining services from milling to line boring and general lathe work. Our skilled machinists can work from your plans and drawings to achieve the first-class results you are looking for. Accuracy is key to the success of any project, and our team has the very latest machinery at their disposal to ensure the very highest levels of engineering precision.

Our machines can undertake a wide range of drilling and milling, to some of the largest equipment components in use by our customers. If parts are unavailable, fabrication and machining may be the only option to keep our clients equipment in operation. If our clients don’t have drawings or design information that’s not a problem here at IKAD. We can reverse engineer a solution for you.

Combined with the skills of our highly motivated machining team and the use of our workshop lifting equipment, we are able to deal with virtually any machining task that our clients present to us. We can also provide on-site machining services for specific tasks.

Our workshop equipment includes the following;